Digitalisation

The fourth Industrial Revolution is with us and more and more devices are being connected to the internet including our cars and even our refrigerators, so why not the equipment in our galvanizing plants.

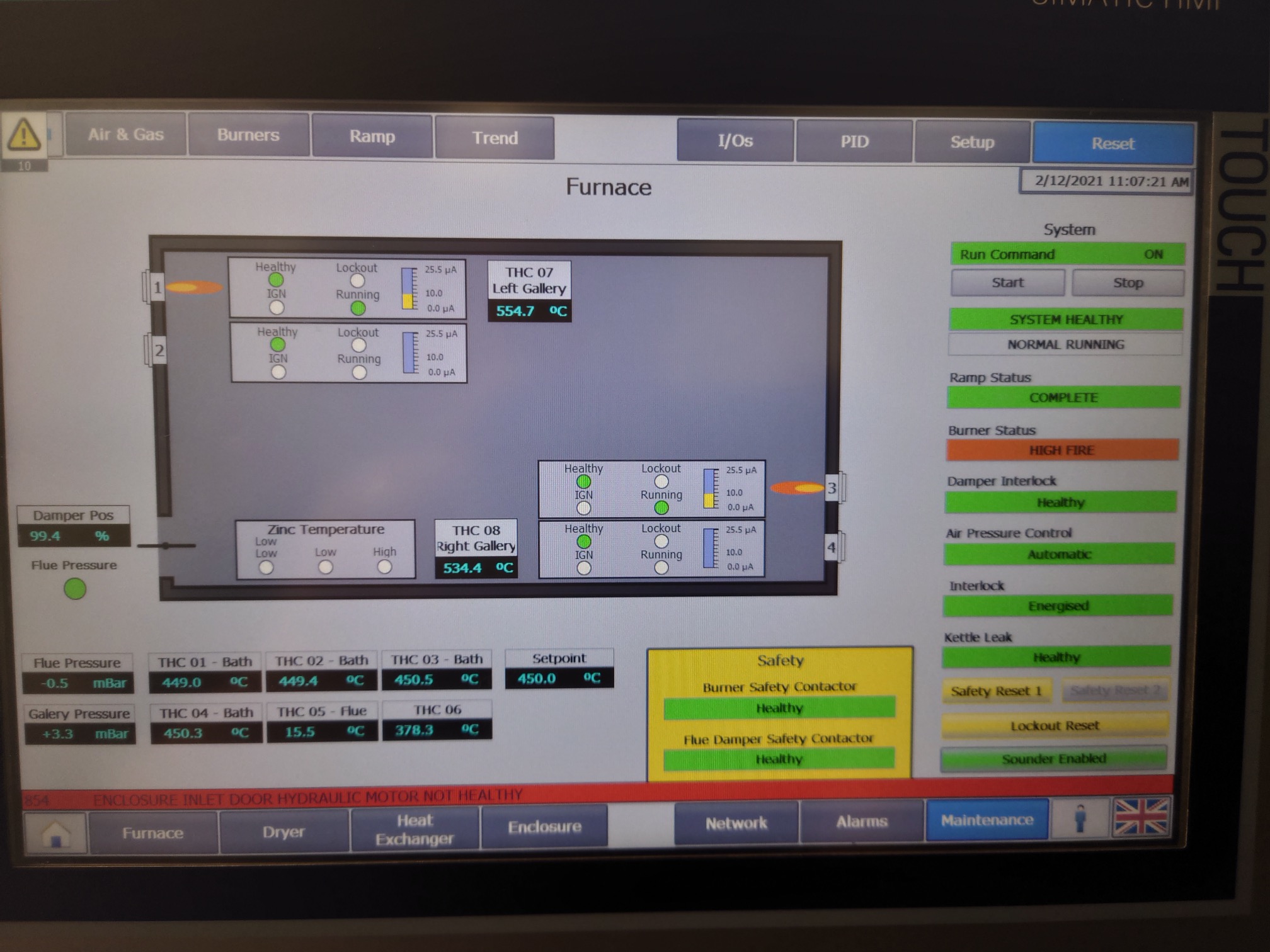

There are many advantages to our IOT solutions including greater process connectivity, reduced maintenance, increased energy efficiency and improved quality.

- Reduce Downtime

- Improve employee wellbeing

- Access critical data – from anywhere

- View historical data

- Reduce your energy consumption

- Increase kettle life

- Reduce zinc consuption

- Improve quality

- Take control of your production cycle

- Improved quality

- One place for all plant data

- Accurate Trents and events to be tracked, understood and analysed